Sound Levels & Mufflers

Last updated: February 22, 2026

Mufflers are required for all ChampCar events—regardless of track policy. Some facilities enforce limits below our series maximum. This page explains the rules, common limits, and proven ways to pass sound reliably.

Sound violations are cumulative from Friday test through Sunday. Tracks may remove non-compliant cars without retests.

Current limits

ChampCar cars must not exceed the series limit, and must also meet any track-specific limits when lower. Always check the Event Supplemental Rules for the official number and meter location.

- ChampCar series maximum: 96 dBA (or lower, if the track requires it)

| Facility (examples) | Typical limit* | Notes |

|---|---|---|

| WeatherTech Raceway Laguna Seca | ~90 dBA | Strict enforcement; meter location can catch intake & exhaust. Orientation matters. |

| NCM Motorsports Park | Below 96 dBA | Event Sups will specify; prepare a quieter configuration. |

| Atlanta Motorsports Park | Below 96 dBA | Be ready with extra muffling/turn-outs. |

| Thompson Speedway | Below 96 dBA | Check meter location; intake roar can trigger hits. |

*Examples only. The Event Supplemental Rules govern.

Pass-sound checklist

- Mufflers installed (plural recommended on higher-output builds). No open pipes—no exceptions.

- Exhaust orientation: exit up and toward driver’s left; avoid pointing at meter locations or walls.

- Quiet the intake: keep filters under the hood; baffle any front inlets; avoid open stacks/ram-air without attenuation.

- Seal the system: no leaks at flanges, collectors, or slip joints; leaks “ring” loud on meters.

- Test under load: dyno or safe road test; free-revving in the paddock doesn’t predict pass/fail.

- Carry a quiet kit: bolt-on turndowns/turn-ups, extra muffler, packing, clamps, and flex joints.

Best practices (what works)

Exhaust hardware

- Use two mufflers in series on stricter tracks; stagger case sizes/resonance frequencies.

- 2.5" tubing often balances flow vs. noise better than oversized pipe on mid-power builds.

- Ball-and-socket or V-band joints: durable, serviceable, and seal well.

- Add a turndown/turn-up elbow to redirect energy away from the meter and hard surfaces.

- Use interlocked-liner flex (not braided-only) to reduce cracking and leaks.

Installation & routing

- Keep clamps tucked up; orient threads/nuts away from curbs and off-track hazards.

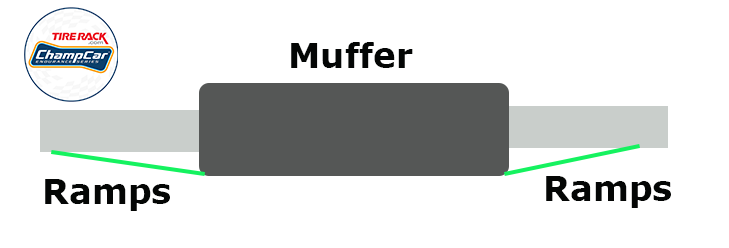

- Skid the muffler face: weld a 16-ga ramp on the leading edge (and trailing if exposed).

- Support weight with proper hangers; let flex joints handle movement—not the flanges.

- Double-nut or safety-wire hot-zone fasteners; copper or multi-layer steel gaskets at collectors.

.png)

At-track fixes & tools

If you get a hit, act fast—don’t risk a second or third strike. Proven triage:

- Add or swap in a second muffler or resonator; extend tailpipe and redirect.

- Clamp-on turndown/up or longer side-exit away from meter.

- Seal leaks (flanges, collectors, slip joints) and re-orient intake tubes underhood.

- Have a basic MIG (flux-core) kit, gloves, wire, brushes for quick repairs.

Parts & resources

FAQ

Do stock exhausts always pass?

No. Even “quiet” OEM systems can fail on strict days or with meter placement. Always bring a backup muffler and turn-pieces.

Is there re-testing?

Tracks control testing. Don’t count on retries. Fix it immediately to avoid strikes.

Questions?

Email media@champcar.org. We want you on track all weekend—set up to be quiet and fast.